Companies should weigh the cost of forecasting errors against the cost for solutions.

Key takeaways

Middle market organizations tend to bear the brunt of current inventory stress.

Technology, collaboration, processes, training and change management are all critical.

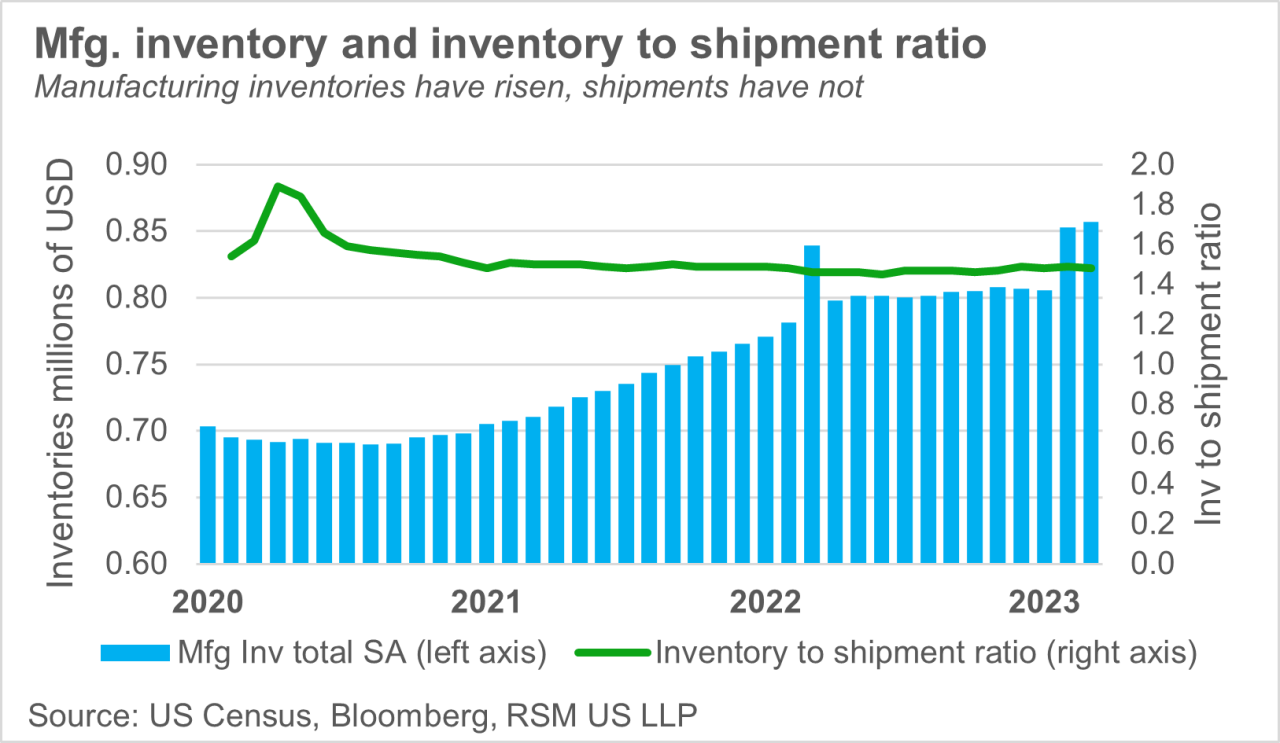

Supply chain stresses, shifting end-consumer demand, and forecasting challenges over the last three years have left many companies grappling with elevated inventory levels. As a potential recession looms, inventory levels pose significant financial risks for businesses, especially those in the industrial and consumer products industries that did not take the necessary steps to reduce inventory levels over the last six months. The market complexities of predicting tomorrow’s demand make it essential for organizations to adopt a data-driven inventory management strategy.

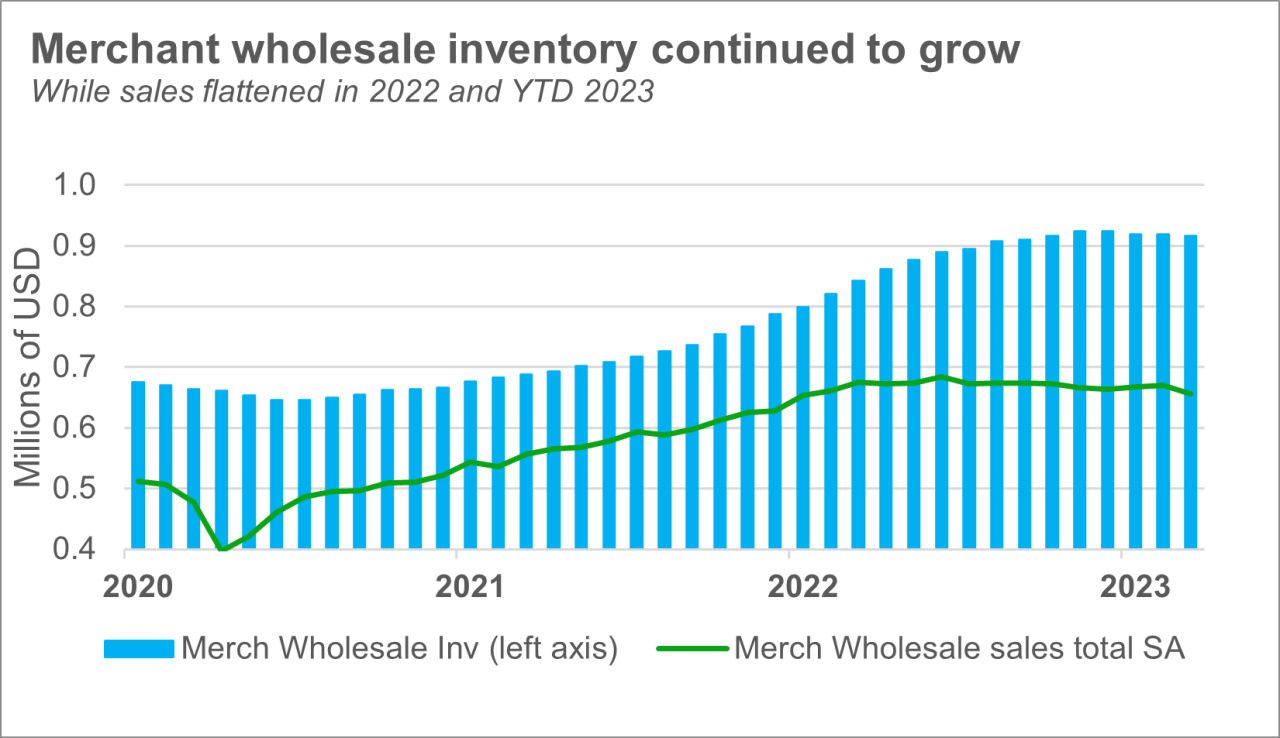

Forty-eight percent of firms with inventories saw their supplies increase in the second quarter, according to the latest RSM US Middle Market Business Index survey—that's down from 52% in the prior period. However, 60% of respondents expect inventory levels to increase over the next six months, a concerning statistic given inventory challenges companies have faced recently.

Gone are the days of making business decisions based solely on intuition or using strategies carried over from the past. With the democratization of predictive analytics and artificial intelligence, more precise technological tools can help companies reduce guesswork, mitigate risk and increase certainty. While the current interest rate environment makes lending for capital-intensive projects more expensive, companies should weigh the cost of forecasting errors against the cost for solutions that drive efficient use of working capital and increase profitability.

While retailers have taken the necessary steps to reduce inventory levels through discounting in the face of waning consumer demand, wholesalers still find themselves grappling with excess inventories. Middle market organizations tend to bear the brunt of current inventory stress, because they have less capacity to absorb margin hits compared to their larger counterparts.

Below we explore key issues, as well as how companies can mitigate the risks associated with current inventory levels and why a data-driven approach is central to such efforts, especially for manufacturers and consumer products companies.

Top inventory issues

Businesses with long lead times to acquire raw materials and inventory that is historically slower moving have been especially hard hit. An example would include heavy-equipment dealers and other wholesalers that source from Asia and have significant resources tied up in working capital. Many have experienced elevations in some or all of these effects:

- Oversupply: Overstocking to compensate for partially filled orders and stockouts

- Stockouts: Product unavailability due to lack of components or logistical supply issues

- Forecast errors: Costly material misses in forecasts which burden working capital with higher inventory levels, limiting companies’ ability to turn goods into cash to fund operations

- Lackluster processes: Inaccurate or unavailable data and a lack of standard, process-driven rigor in inventory management

- Too many SKUs: The proliferation of product offerings and variations has been a pain point, especially because some of that product is slow-moving and low-margin, trapping cash

Consumer spending has remained resilient overall, but with RSM US LLP putting the chance of a recession at 75% over the next 11 months, potential job losses will deflate the tailwinds supporting consumer spending patterns. Cracks are already beginning to form in consumers' willingness to spend on apparel, home furnishings, recreational goods and other categories that experienced outsize growth earlier in the pandemic.

Adopting a data-driven approach to inventory management

Businesses that operate on thin or shrinking margins are continuously investing to make core processes more efficient and integrate predictive analytics throughout the organization. Typical results RSM has seen for successful projects intended to address inefficiencies include significant returns on investment, such as 8% to 18% savings in procurement, 5% to 30% reductions in operational costs and 5% to 22% in logistics savings.

Unsure how to tackle inventory management in the face of volatile supply?

Here are some of the most critical areas of focus for businesses that want to adopt or improve their data-driven approaches to inventory management:

- Technology: Implement or optimize inventory management software and leverage data analytics and supply chain management systems to support data-driven decision making. Predictive analytics should include both the company’s internal data and external macroeconomic real-time data.

- Collaboration: Build partnerships with suppliers, distributors, and customers to gain insights into market trends and forecast demand accurately. Optimizing shared data among third parties is ideal; but if it is unworkable, then businesses need to collaborate with suppliers more frequently.

- Processes: Form governance policies based on statistical analysis for key areas like reorder points, target levels, and costs by inventory segment on an ongoing basis.

- Training and change management: Technology is only a useful tool if organizations adopt a continuous improvement approach and well-trained managers monitor and measure the results. Invest in training and budget for it as part of the program cost.

Company data frequently resides in multiple fragmented systems internally, making analysis costly, untimely, and less frequent than necessary. Focusing on the four areas above will make inventory management improvement efforts more likely to succeed.

Additional risk mitigation strategies

Because cash is ultimately king, there are two additional areas that companies cannot afford to overlook as they seek to mitigate inventory-related risk: cash forecasting and stress-testing financial statements. An up-to-date, 13-week cash flow analysis provides timely insights into potential financing needs. Stress-testing key variable inputs—such as sales volumes and key operating costs—on financial statements is also valuable. In more volatile markets, it is also critical to identify forecast levels that require management intervention.

If the supply and demand roller coaster of the last few years is not enough to motivate companies to prioritize a data-driven inventory approach, the prospect of a potential recession should spur them to action. Businesses that want to emerge on the other side of the expected slowdown in a position of strength should implement technologies now that can help them better predict demand, conduct cash forecasting and plan with confidence.

RSM contributors

The Real Economy Canada

A quarterly economic report for middle market business leaders.

Industry insights

Industry-specific insights for the middle market.